- Home

- About Us

-

Project Related Information

- Rehabilitation of the Reedy Creek KRA

- Why is this project different?

- Land Use Context

- Site Baseline Conditions

- Key Project Drivers

- Why Now?

- Development Application Components

- Site Specifics

- What is the Reedy Creek KRA?

- What is the West Burleigh Project?

- Project Benefits

- Timeline - RCKRA & WBCWRR Project

- How will the Reedy Creek Project be built?

- What will happen at West Burleigh?

- Proposed Haul Routes

-

Fact Sheets

- Quarry Industry

- The Quarrying Process

- Recycling and Resource Recovery

- What is non-putrescible waste?

- What is a circular economy?

- What is a Key Resource Area?

- Boral’s Environmental Strategy

- Boral's visual strategy

- Dust Management at Boral

- What is Respirable Crystalline Silica (RCS)?

- Hours of operation - Reedy Creek KRA

- Reedy Creek Project Noise Assessment

- West Burleigh Project Noise Assessment

- Cumulative Noise Impact Assessment

- Reedy Creek Air Quality Assessment

- West Burleigh Air Quality Assessment

- Cumulative Air Quality Impact Assessment

- Blasting and Vibration Fact Sheet

- Visual Amenity Fact Sheet RCKRA

- Visual Amenity Fact Sheet WBCWRR

- Terrestrial Ecology Assessment - RCKRA

- Terrestrial Ecology Assessment - WBCWRR

- Traffic Strategy Fact Sheet

- RCKRA Site Access & Local Road Upgrades

- Contact Us

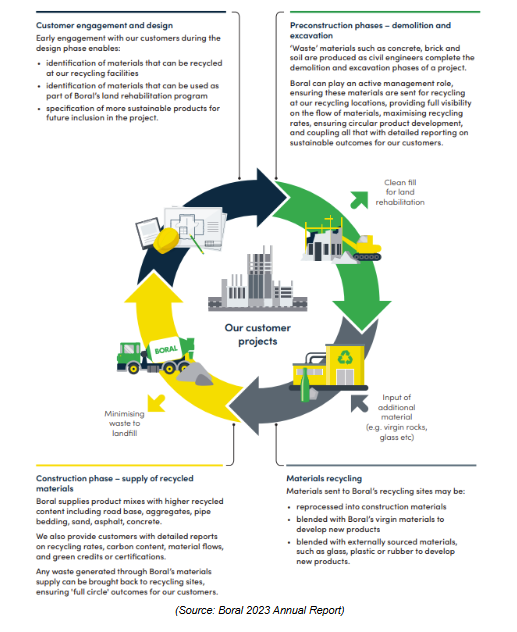

What is a circular economy?

In a circular economy, things are made and consumed in a way that minimizes our use of the world’s resources, cuts waste and reduces carbon emissions.

Products are kept in use for as long as possible, through repairing, recycling and redesign – so they can be used again and again.

The circular economy is an alternative to traditional linear economies, where we take resources, make things, consume them and throw them away. This way of living uses up finite raw materials and produces vast quantities of waste.

In an ideal circular economy, products are redesigned so they last through several life cycles – rather than being immediately recycled.

In Australia 26.8 million tonnes of construction and demolition waste is generated in annually, with 63% of these materials now being reused as part of the circular economy.

The use of recycled materials in road, infrastructure and building construction is increasingly being mandated by governments and requested by customers.

Whilst recycled aggregates will play an important role in continuing to help meet future demand for aggregates, they will supplement hard rock supply. They cannot replace the need for new reserves of hard rock and additional quarry capacity to meet community need to 2050 and beyond.

How are Circular Economy principles applied to Boral’s business model?

Most demolition waste such as brick, concrete, and steel are not at the end of their life cycle as a material, so there is a significant opportunity to recycle. Similarly, excavation waste materials such as sand, stone, and fill can be reclaimed, blended, or repurposed.

In a seamless process, demolition and excavation waste is collected from site and transported to a local Boral recycling centre where it is processed and recycled for use in new, more sustainable building materials. These include:

• Recycled aggregates

• Specified and non-specified recycled road base

• Reclaimed concrete, sand and asphalt

• Specified and non-specified select fill

• Recycling pipe bedding sand; and others