- Home

- About Us

-

Project Related Information

- Rehabilitation of the Reedy Creek KRA

- Why is this project different?

- Land Use Context

- Site Baseline Conditions

- Key Project Drivers

- Why Now?

- Development Application Components

- Site Specifics

- What is the Reedy Creek KRA?

- What is the West Burleigh Project?

- Project Benefits

- Timeline - RCKRA & WBCWRR Project

- How will the Reedy Creek Project be built?

- What will happen at West Burleigh?

- Proposed Haul Routes

-

Fact Sheets

- Quarry Industry

- The Quarrying Process

- Recycling and Resource Recovery

- What is non-putrescible waste?

- What is a circular economy?

- What is a Key Resource Area?

- Boral’s Environmental Strategy

- Boral's visual strategy

- Dust Management at Boral

- What is Respirable Crystalline Silica (RCS)?

- Hours of operation - Reedy Creek KRA

- Reedy Creek Project Noise Assessment

- West Burleigh Project Noise Assessment

- Cumulative Noise Impact Assessment

- Reedy Creek Air Quality Assessment

- West Burleigh Air Quality Assessment

- Cumulative Air Quality Impact Assessment

- Blasting and Vibration Fact Sheet

- Visual Amenity Fact Sheet RCKRA

- Visual Amenity Fact Sheet WBCWRR

- Terrestrial Ecology Assessment - RCKRA

- Terrestrial Ecology Assessment - WBCWRR

- Traffic Strategy Fact Sheet

- RCKRA Site Access & Local Road Upgrades

- Contact Us

Blasting and Vibration Fact Sheet

What is Blasting?

There are a few ways to extract ‘hard’ rock, but the most common and effective method is ‘controlled blasting’. As blasting is very precise practice, each blast is designed and carried out by an independent third-party blast expert.

A blast design is a carefully planned operation that involves drilling into the rock in a specified pattern, then placing a very precise amount of explosive in the holes. The explosives are then detonated in a precise sequence, designed to maximise the efficiency of rock breakage while minimising noise, vibration and dust. One of the advantages of blasting is that it reduces the need to operate large heavy equipment to extract the rock, in turn reducing noise and greenhouse gas emissions.

Depending on how close you live to a quarry, you may notice some short-term vibration or noise associated with blasting activities that typically last for around 4 seconds per blast.

What safeguards are in place during blasting?

Strict national safety regulations apply to protect neighbouring homes, buildings and public places from the potential effects of blasting. Blasting operations must adhere to prescribed limits stipulated by the relevant regulatory authority that are well below the vibration levels which could cause structural or cosmetic damage. Blasts are monitored at different locations with sensitive ground and air vibration equipment to ensure they remain within regulations.

What else should I know about blasting?

Apart from vibration, the energy used in blasting to move and break rocks may also result in some noise and dust. The further you are away from the quarry, the less you will notice these effects. A quarry’s strict operating conditions requires that every action be taken to reduce these effects.

Blasting assessment key findings – Reedy Creek Key Resource Area Project

An independent Blasting Assessment was conducted, which assessed potential blasting vibration and air-blast overpressure impacts and flyrock risk from the RCKRA Project. This assessment is based on analysis and modelling of vibration and air-blast overpressure impacts through predictive models established from 700 measurements of blasting impacts in areas surrounding the West Burleigh Quarry.

The use of this large, existing blasting database is preferred over the use of a small number of measurements from any trial blasting program, due to its greater statistical variability and significance.

The submitted assessment of blasting and vibration has been undertaken against the Queensland Government Noise and Vibration from Blasting Guideline (ESR/2016/2169 - Version 3.02) (Noise and Vibration Guideline).

The assessment undertaken demonstrates that full compliance with the vibration and air-blast overpressure limits set out in the Noise and Vibration Guideline can be achieved for all phases of development and recommends management measures for two sensitive blasting areas: one located at the northern edge of the proposed quarry pit, and one located at the south-eastern edge of the infrastructure area. In these two sensitive areas, blasting will involve two independently delayed decks per blasthole. Outside of these two sensitive blasting areas, the RCKRA Project blasting will follow conventional practices of a single charge column in each blast hole.

These necessary management measures are reflected in the RCKRA Site Based Management Plan.

The implementation of the abovementioned management measures will ensure that the RCKRA Project will not result in any unacceptable amenity impacts arising from operational blasting. The design of the pit and the on-going blasting management approaches will ensure that there are no unacceptable vibration and air-blast overpressure impacts to nearby residential premises.

Flyrock risk is also shown to be effectively zero for all structures in all surrounding communities, for all blasting in all four operational phases of pit development.

Blasting impact compliance conditions for Boral Reedy Creek Key Resource Area Project

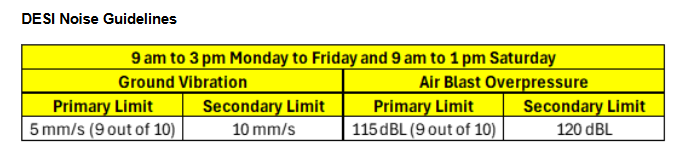

Compliance with the primary limits is required for 9 out of 10 consecutive blasts, and compliance with the secondary limits is required for 100% of blasts.

While human perception of vibration commences around 0.5 mm/s, and air blast overpressure levels around 80 dBL for very sensitive people, the DESI guidelines identify levels to “minimise annoyance and discomfort” to nearby residents.

Importantly, the guidelines also state “People are able to detect vibration at levels much lower than those required to cause even superficial damage to the most susceptible structures”.

The limits prescribed DESI are lower than any other known international limit, with published international studies indicating that compliance with the guidelines in the table above ensures that the blasting impact levels of vibration and air blast not only represent acceptable outcomes to occupants of structures, but also are levels incapable of causing superficial damage to structures.

Proposed Blasting Practices for the RCKRA Project

Blasting in the proposed Reedy Creek pit will be conducted on 12 metre benches, using 89 mm diameter blastholes, and a pumped emulsion product supplied by an explosives services provider, such as Orica. This scale of blasting is very conventional throughout Queensland and Australia, and the same as the practices at the nearby Boral West Burleigh Quarry.

All production blasts will be monitored by an independent specialist company and will involve multiple locations within the nearest communities of Old Burleigh Town, Kingsholm Estate, Observatory Estate, Tallebudgera Creek Road, and Tuesday Drive.

To mitigate factors likely to affect perception and amenity, including the frequency of occurrence of blasting, duration of the vibration disturbance, and separation distances at the proposed Reedy Creek Key Resource Area Project:

-

Duration of disturbance at sensitive sites, including both ground vibration and airblast overpressure effects, is typically up to 4 seconds for each blast.

-

The frequency of occurrence of blasting, will typically be twice per month, corresponding to a disturbance period of approximately 8 seconds per month, and 96 seconds per year.

-

The minimum separation distance (buffer width) between private housing and the planned future pit production blasting area is approximately 240 metres on the north-western side (The Observatory), and a minimum of approximately 450 metres in all other directions.

-

The minimum separation distance (buffer width) between private housing and the planned future construction blasting area is approximately 290 metres on the south-eastern side (Tallebudgera Creek Road), and a minimum of approximately 450 metres in all other directions.